On Jan. 10, House Bill 1103 was reintroduced for the fourth time in the Washington State Legislature. The bill aims to lessen environmental harm during the production of building materials by requiring state contractors to have Environmental Production Decelerating (EPD) documents for their projects. EPDs are documents companies make to track and report the environmental impact of their products. Materials contractors and architects typically need for construction include concrete, cement and asphalt. One such local business is Cadman, which supplies asphalt and concrete from its twenty five plants in the Pacific Northwest to contractors across Washington and Oregon. One Cadman asphalt plant is in downtown Kenmore where it sits atop Lake Washington next to the Burke Gilman Trail.

Over the past three years, Kenmore citizens have expressed growing concern about Cadman’s environmental impact on their health. According to King 5 News, Kenmore citizen Kate Donaldson, who lives downwind from the plant, said that she can taste the asphalt in the air. Kenmore Development Services Director Bryan Hampson said in an interview with Nordic News that the scrutiny is reasonable and amplified due to the plant’s urban location.

“If I was in their shoes, I probably would have done the same thing,” said Hampson. “But what we are typically seeing right now is the odor isn’t that pleasant to some and bothers a lot of people.”

Kenmore citizens could simply be reporting breathing in the odor from the plant, but anyone living near a plant also experiences carbon emissions in their environment. Alex Ianchenko, an architect at Miller Hull and researcher on the climate impacts of buildings, said the impact of these emissions depends on the processes the plant uses. Ianchenko said that a company can screw up a plant anywhere and can do well with a plant anywhere. She said that concrete cannot be made without emitting carbon, which is harmful to the environment.

“To make cement, we burn lime, and that off-gases greenhouses gases into the atmosphere. So just because of the nature of this chemical reaction, we will never be able to make cement the way we make cement now and have it be carbon neutral. But the technology exists to start replacing cement with products that do the same job,” said Ianchenko.

Cadman receives permits from and is regulated by the Puget Sound Clean Air Agency. Additionally, Hampson said that the city hired a professional expert to look at the different materials being produced by the site. According to Ianchenko, there are no laws that dictate the total amount of carbon impact a new building can have. However, House Bill 1103 would provide incentive for companies to meet high environmental standards by supplying EPDs.

“EPDs have not only information about climate impacts, which is an air thing, but also usually include other environmental impacts like nitrification, which is a measure of water pollution, acidification, which is another measure of air pollution, and smog,” said Ianchenko.

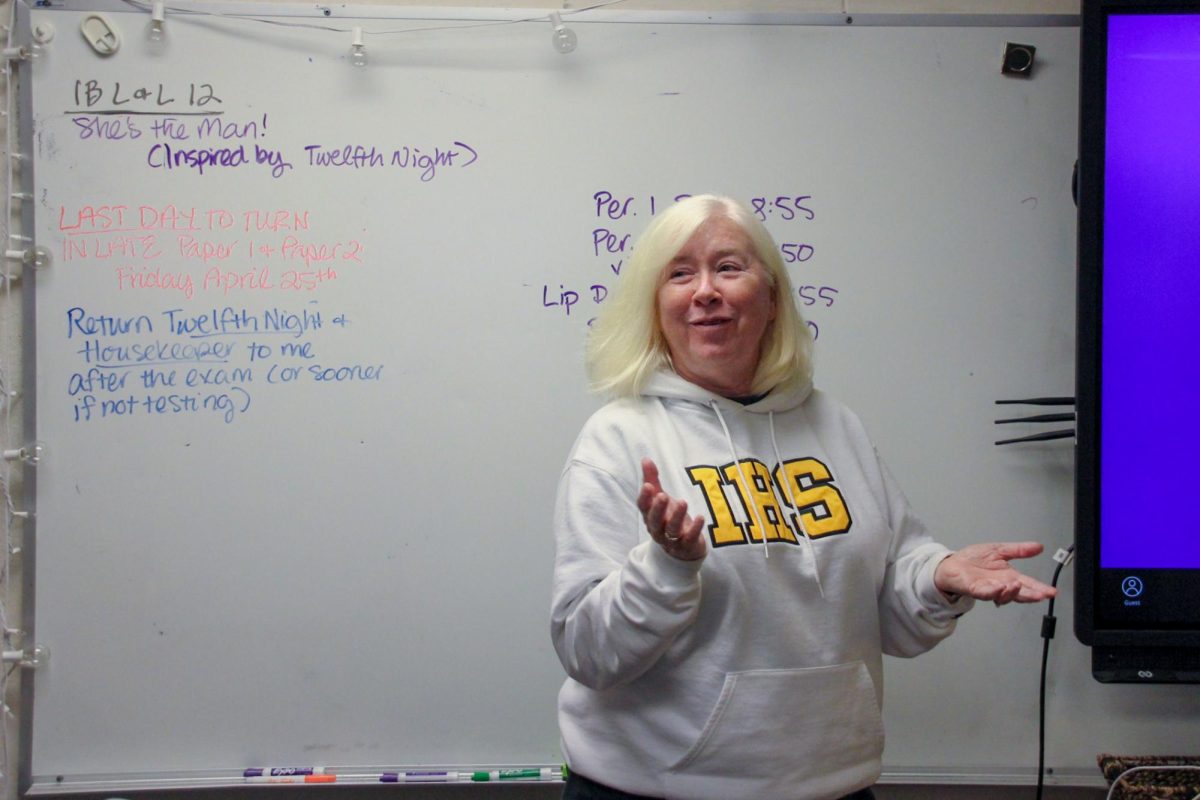

The challenge of these documents isn’t necessarily requiring companies to make them available, as anyone buying Cadman’s products can request an EPD. Ianchenko said the true challenge is relaying this information in a way that is impactful and easy to understand.

“I’m steeped in this work, but still, if I see a table of these numbers without context, it’s very difficult to interpret what that means in terms of environmental impact. People don’t care about the 50 kilograms of CO2 equivalent. A report like an EPD might say, ‘to produce a kilogram of cement, we release five kilograms of CO2 into the air.’ And yeah, that’s great, and in a way, I understand the environmental impact, but I don’t [understand] what that means for causing climate change as a whole,” said Ianchenko.

Ianchenko said she believes that Cadman is not the only plant that needs to change its environmental policies and that the whole industry needs to shift. Supplementary cementitious materials are compounds that have the potential to replace concrete. Additionally, a new climate change solution, carbon scrubbing, aims to remove billions of tons of carbon dioxide from the atmosphere. As of 2019, there are ten carbon scrubbing facilities in the United States.

Besides utilizing technology, Ianchenko explained that writing legislation and fostering environmental literacy are ways to hold companies like Cadman accountable for their effect on the environment in the future.

“As [architects], we need to develop a sort of literacy to think about environmental impacts of our materials all the time. I don’t think that we will ever be able to decarbonize cement completely, because even if we move the grid to renewable sources entirely, the process of making cement still requires the emission of carbon,” said Ianchenko.